FROM TREE TO CUP

UNDERSTANDING COFFEE’S CARBON FOOTPRINT

UNDERSTANDING COFFEE’S CARBON FOOTPRINT

NOTES, CREDITS, REFERENCES

*interpretation graphics Quantis LCA (2023)

European market adaptation Life Cycle Asessment (LCA) of a lungo cup of coffee made from a Nespresso original capsule compared with other coffee systems in Europe

Carbon Footprint of the Nespresso Original System

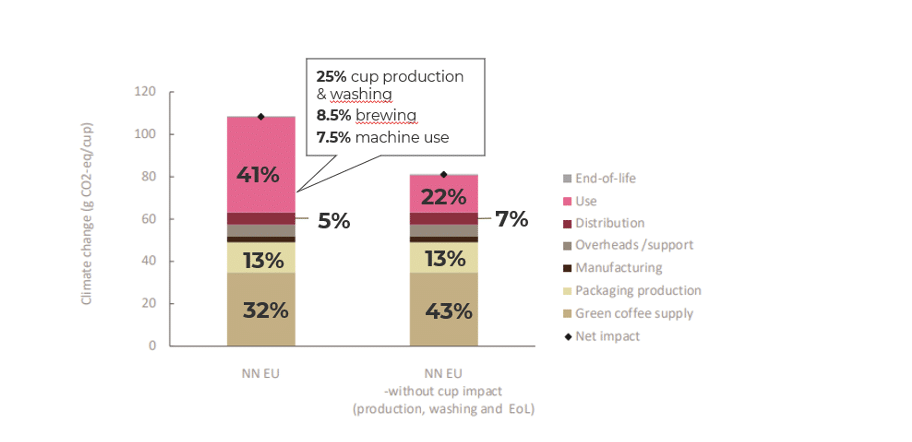

A 110 ml cup of Nespresso coffee emits approximately 108 g CO₂-equivalent on the European market. The largest contributors to this carbon footprint are:

-

Use phase (41%), primarily driven by:

-

Cup production and washing: 25%

-

Coffee brewing: 8.5%

-

Machine manufacturing, distribution, and cleaning: 7.5%

-

-

Green coffee supply: 32%

-

Packaging: 13%, broken down into:

-

Primary (capsule) packaging: 10%

-

Secondary packaging (sleeves and cartons): 3%

-

-

Distribution: 5%

-

Overheads and support services: 5%

-

Manufacturing: 3%

-

End-of-life (recycling, incineration, or landfill of packaging and capsules): ~0% (neither significant impact nor benefit)

The cup-related impacts (production, washing, and end-of-life) -though beyond the control of the coffee provider and consistent across systems, are included in the total lifecycle as they are essential for consumption. These contribute 27 g CO₂-eq, or 25% of the total footprint.

To simplify the product’s impact for consumers, Nespresso also provides a view excluding the cup impacts. In this adjusted scenario, the contributions shift as follows:

-

Green coffee: 43%

-

Machine use: 22%

-

Capsule production: 13%

-

Distribution: 7%

-

Overheads: 7%

-

Other packaging: 3%

-

Manufacturing: 3%

-

End-of-life: 0.3%

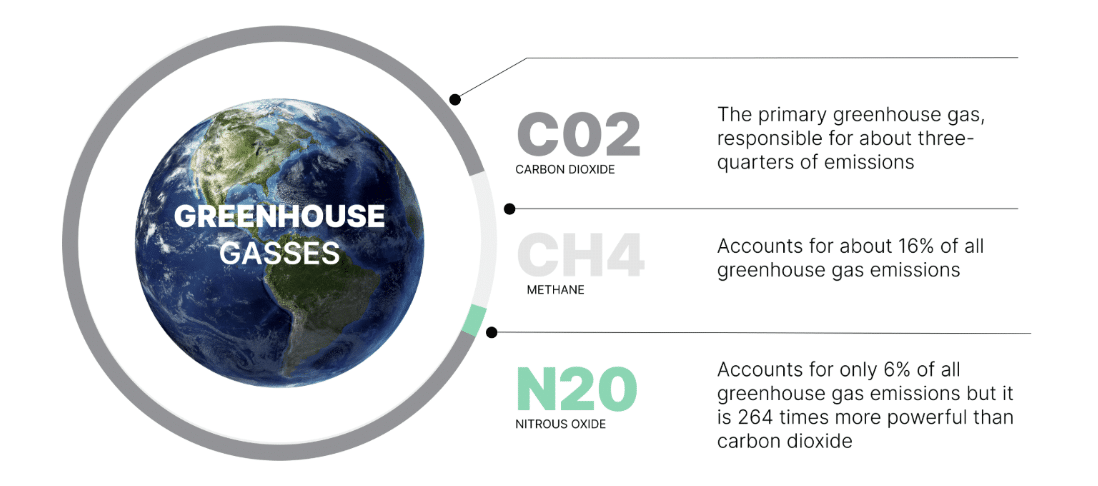

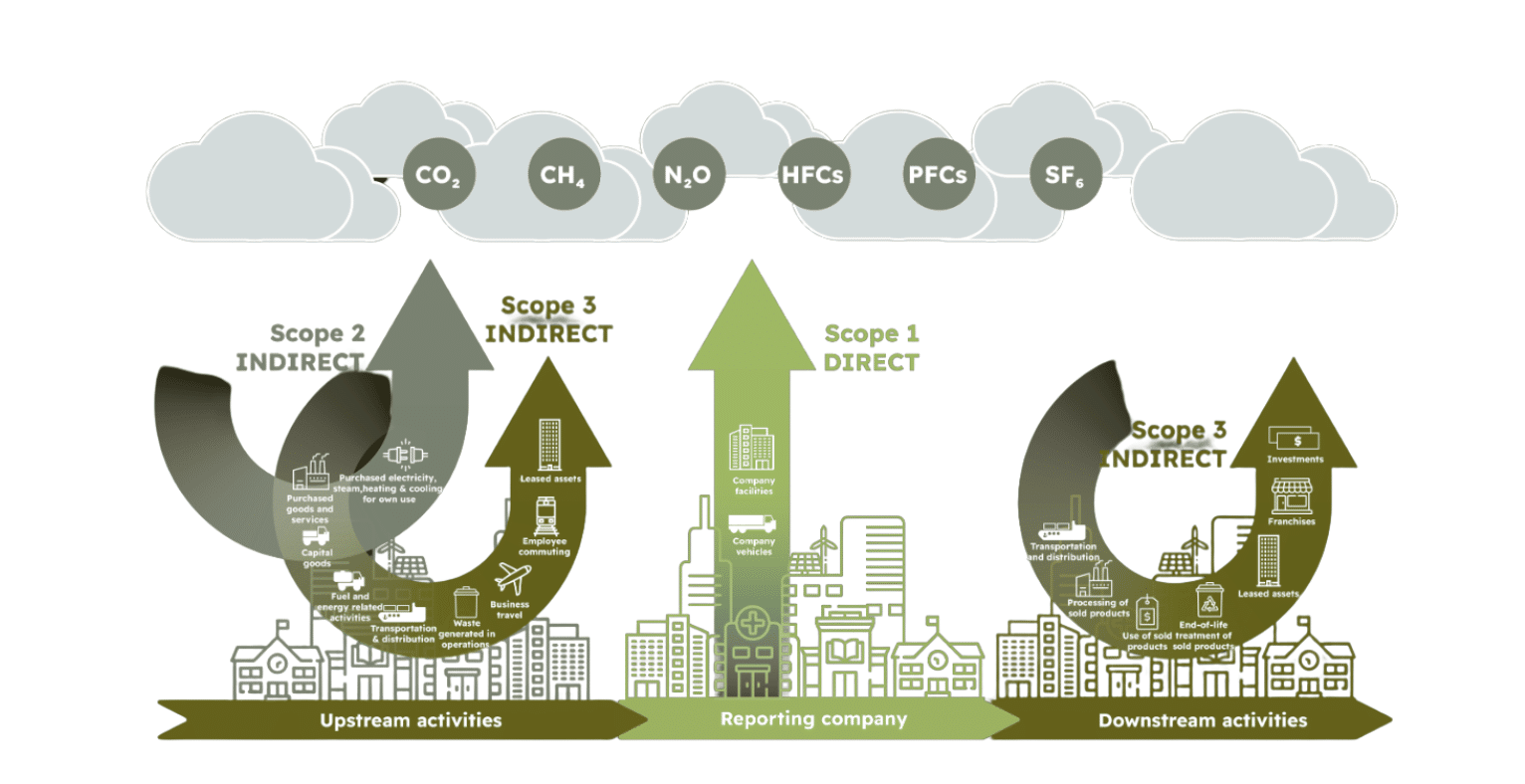

Carbon Footprint: The carbon footprint is a measure of the potential impact on climate change. It takes into account the capacity of a greenhouse gas to influence radiative forces, expressed in terms of a reference substance and specified time horizon (100 years). The impact metric is expressed in kg CO2-eq.

End of life: The end-of-life stage includes the collection and treatment of the different packaging items, the coffee grounds, the machine and the cup.

LCA: Life Cycle Assessment

EFICO – Harvesting Coffee and Carbon

EFICO – EFICO plants trees with impact in Tanzania

CUPRIMA – Recents Developments in coffee processing – unlocking flavours

EFICO FOUNDATION – Kilimanjaro Water and Food for All – Project

EFICO FOUNDATION 20Y Flagship Project ‘Kilimanjaro Water & Food for All’

EFICO – Nicaragua SHG Rainforest Alliance Forest Positive Coffee

EFICO – Insights and Takeaways from Efico’s Sustainability Team for EUDR Compliance

EFICO – Communication of Progress Y 2024

CDP – Brewing a Sustainable Future: the Carbon Footprint of your Coffee

ScienceDirect – Comparing carbon agronomic footprint and sequestration in Central American coffee agroforestry systems and assessing trade-offs with economic returns

Barista Hustle – The Decision Tree – The Carbon Footprint of Coffee Cultivation

Espresso Outlet – Eco-friendly Wastewater Treatment Solutions for Coffee Processing Facilities

CIRAD Agricultural Research for Development – Review on Green Coffee Carbon Footprint

USAID – Scaling up Sustainable Robusta Coffee Production in Vietnam – Reducing carbon footprints while improving farm profitability

Nespresso – The Positive Cup – 2022 Progress Report